Technologies

Designing

The variety of materials used for production, the "golden hands" of our employees, our own unique technologies and the commitment of our partners allow us to do outstanding, perfectly designed, ergonomic and simply beautiful things.

It all starts with an idea. A sketch is enough for us to make a project: construction, selection of materials, visualization and 3D model. We provide professional technological consulting. We also create our own projects.

Carpentery

Wood is the basic raw material used in Neo Spiro. We process solid oak, ash, beech and alder wood. We also use furniture boards, plywood, different veneers, HPL Fenix boards and FORBO furniture linoleum. The beauty of our products is emphasized by high-quality varnishes from the Italian company ICA and oil waxes from the renowned OSMO and the Austrian Adler.

The best carpenters and CNC machine operators from our manufacture work manually but also operate conventional carpentry machines and numerically controlled milling plotters.

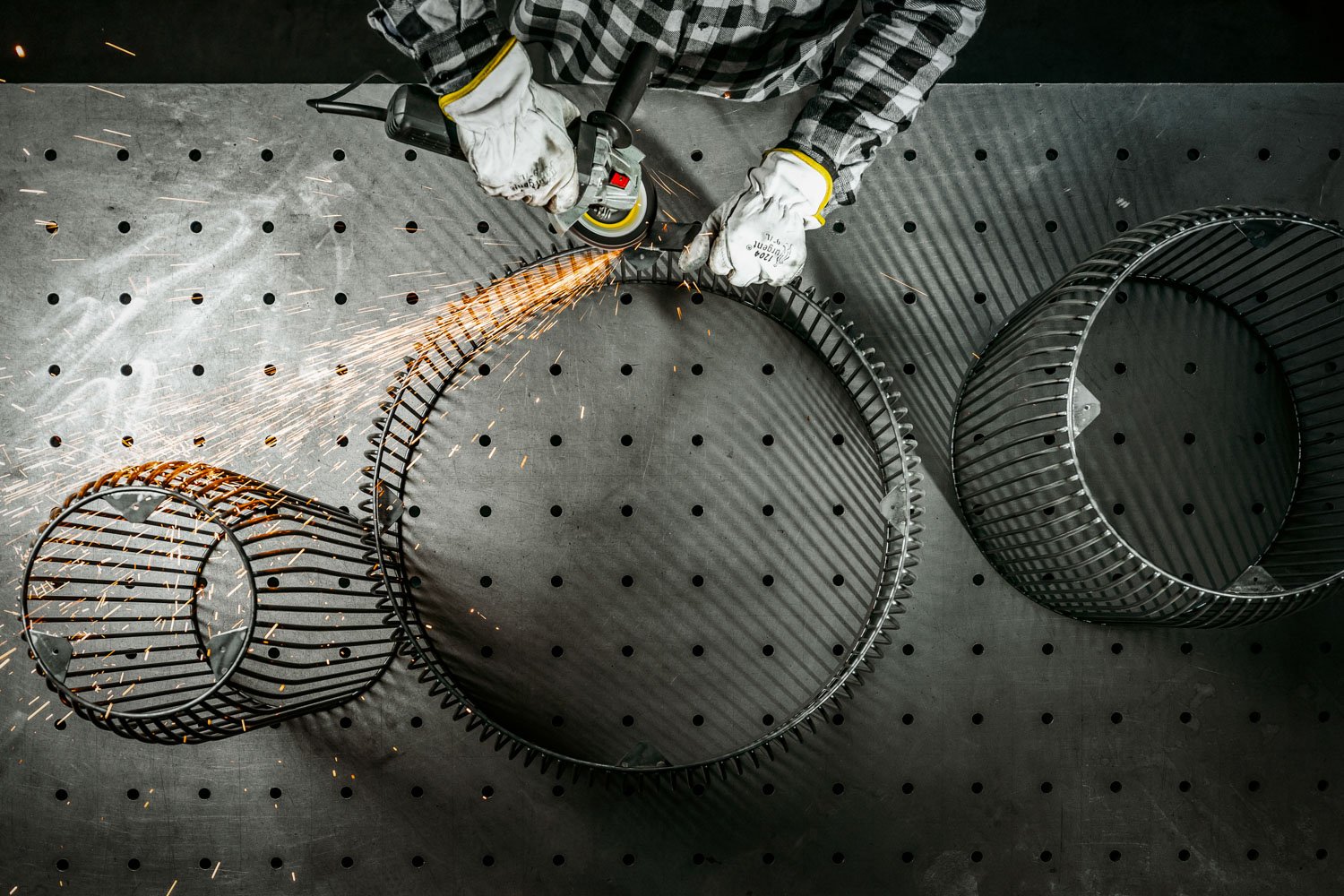

Metalworking

Our technological capabilities also include metal processing: black steel, stainless steel and, in special applications, also aluminium. We weld in TiG and Mag technology. Access to the CNC laser technology allows to cut any shapes in steel sheets and profiles. Rounded bowls are elements of coffee tables, perfect for the terrace and garden.

Paintshop

The Italian Axalta also produces excellent powder paints for us, which protect the surface of metal products. We have been cooperating with Mr. Piotr's powder paint shop for a long time.

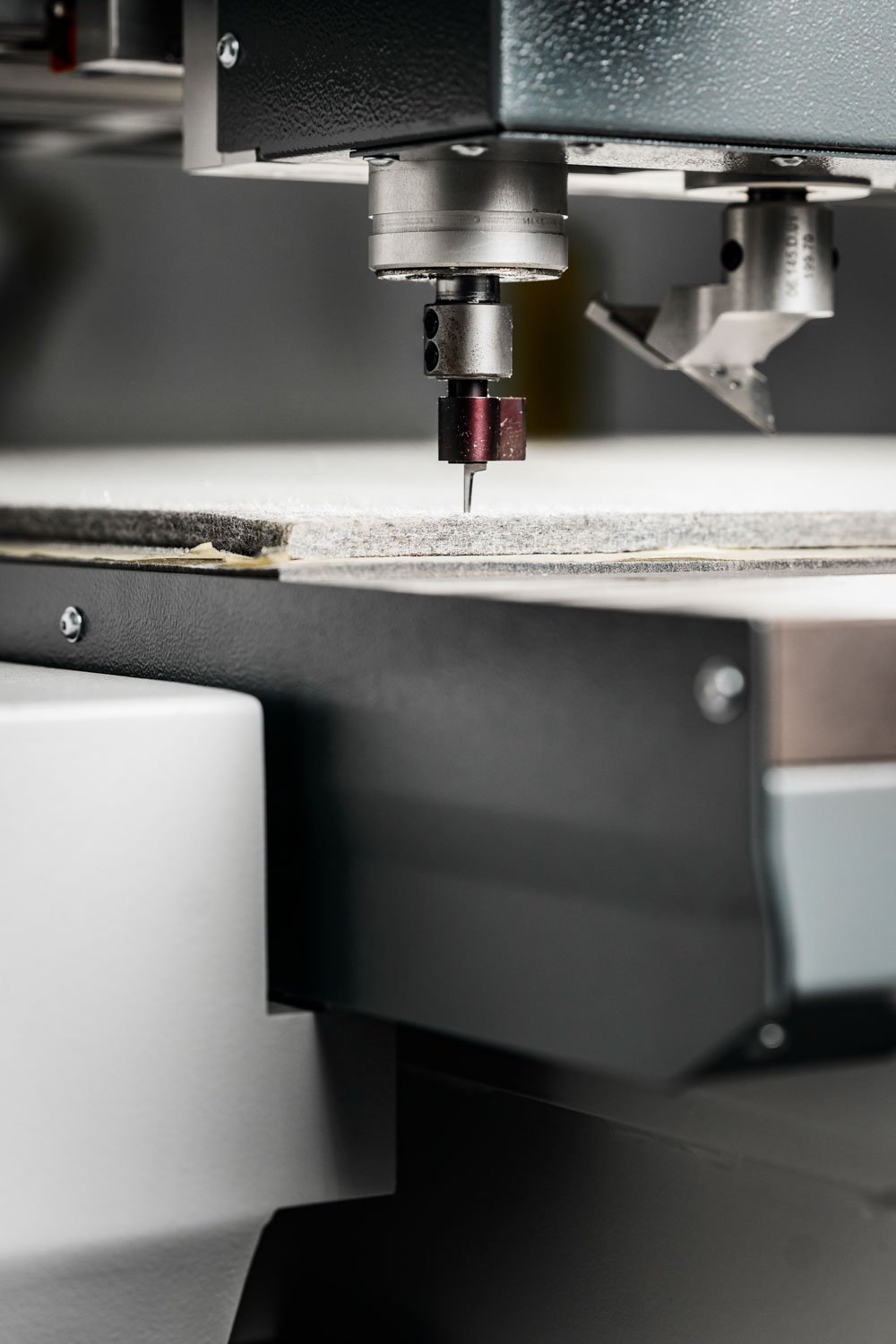

PET felt

At the customer's request, we upholster elements of seats and soundproofing surfaces.

And so we have started our production adventure with PET felt. Our customers ordered lamps made of material that muffles offices. We met the challenge. We are constantly working on expanding the offer using recycled PET felt.

Its main advantage is noise absorption. The softness and ease of processing confirm the accuracy of the choice of this material for the production of elements that improve the acoustics and coziness of work places.

Glass processing

We also provide glass processing services in cooperation with our partners. We offer titanium mirrors, colored Lacobel and hardened worktops in any shape. Waterjet technology is irreplaceable in the cutting of glass and ceramic sinter.

UV Print

One of our cooperator has a plotter for UV printing on a hard surface. A print is applied to the plywood prepared by us. That’s how our furniture for children are produced. We also know how to prepare the glass to faithfully reproduce photos. We will soon try to print patterns on ceramic substrates.

Photo studio

We photograph in our own studio. We use the photos for promotional purposes and for making 3D models. At the client's request, we can organize a photo shoot of the ordered products.

The process of our work always starts with matching your idea to technologies. We propose solutions, discuss them, then go to production phase.

1. Your idea

All you need to get started is a sketch or a short conversation.

2. Our concept

We select materials, construction and technology. Then we create an initial visualization and discuss it with you.

3. Project and prototype

We implement projects with appropriate technologies. A prototype is created at the customer's request.

4. Production

Our employees, with the support of machines and modern technologies, make perfect products.

5. Shipping

The products are secured in such a way that they reach you undamaged. We ship with responsible carriers.